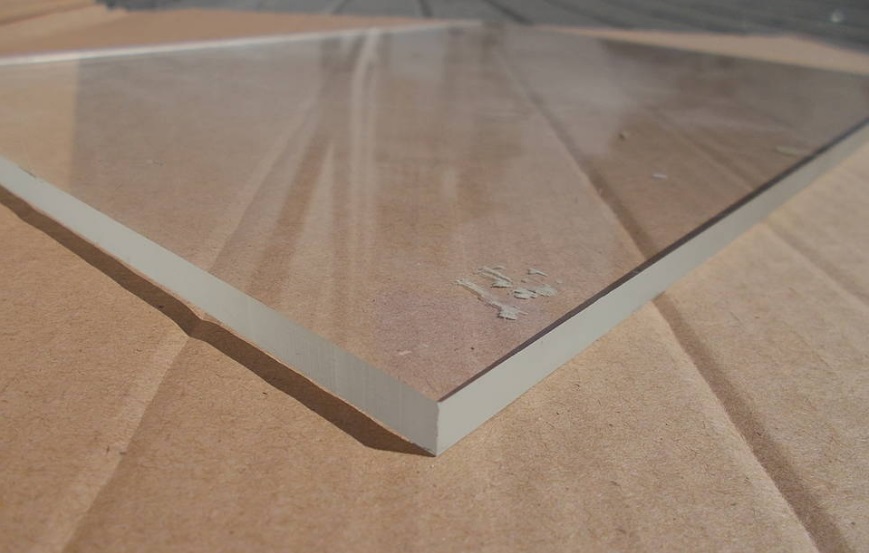

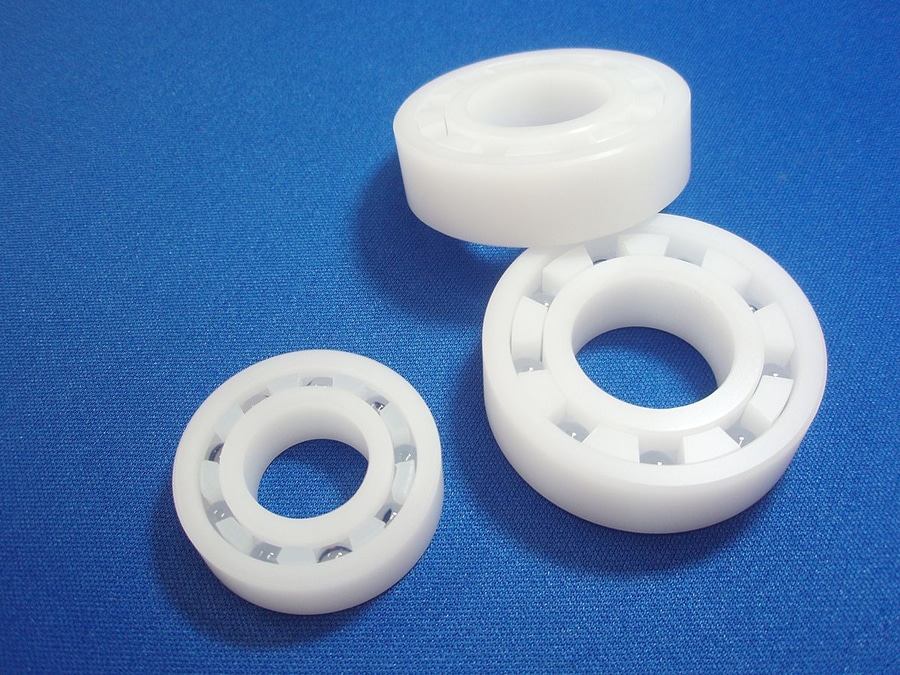

LORETA s.r.o. is a long-standing manufacturer of plastic moldings

It has been building its position on the market since 1990. The company's goal is the production of plastic moldings that will meet the high demands of customers on the quality of individual products, the quality of production and the technology of the production process, delivery dates and other specific requirements from customers.